Efficient Low-Temperature Energy Conversion

INNOVATIVE ORGANIC RANKINE CYCLE PROCESS

REPLACE TURBINE WITH A FREE-PISTON ENGINE

SOPHISTICATED PATENT-PENDING SMART CONTROL SYSTEM

0 GWh

Annual Energy Savings per 100MW Data Center

0kT

Greenhouse Gas Reduction per 100MW Data Center

0°C

Minimum Input Temperature

0

Patents Filed

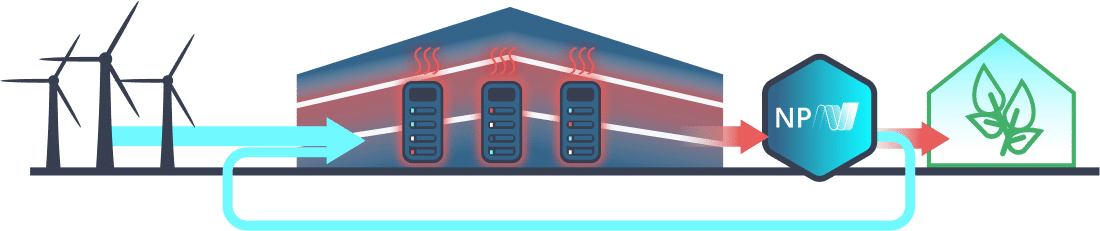

Harnessing Waste Heat For Data Center Power

1.4 PUE

AIR-COOLED DATA CENTRES1.03 PUE

LIQUID-COOLED DATA CENTRES0.94 PUE

Liquid-Cooled NovoPowerFeatures

Advanced Control

Smart system adjusts for max efficiency

Efficiency

Optimized for low-grade waste heat

Stability

Consistent power output in variable conditions

Low Maintenance

Minimal upkeep for continuous operation

Compact Design

Fits into existing infrastructure easily

Modular

Scalable and flexible to fit energy needs

How It Works

Capture

In immersion cooling, heat from the servers is absorbed by the nonconducting liquid in which they are immersed. In direct-to-chip cooling, the servers are in racks with tiny heat exchangers attached to the processors. This method ensures efficient heat absorption directly at the source.

Convert

The hot fluid from the servers is circulated through a heat exchanger, which uses the heat to vaporize an environmentally friendly working fluid. This pressurized vapor expands, pushing a piston through a cylinder (a “free-piston expander”), driving a generator to produce electricity.

Control

NovoPower’s sophisticated control system seamlessly adapts in real-time by varying the flows and parameters of the electrical system. This makes our Low-Temperature HTE™ (heat-to-electricity) system the only viable solution for liquid-cooled data centers. It ensures optimal performance and energy efficiency.

Ready to Elevate Your Data Center?

Contact us today to learn more about how NovoPower's innovative heat-to-electricity technology can enhance your operations. Our team of experts is ready to help you implement the most efficient and sustainable energy solutions available.

Contact Us